|

Shijiazhuang Sude Machinery Equipment Co., Ltd.

|

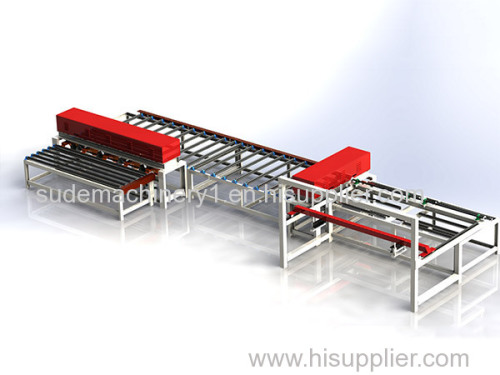

Automation Gypsum Cutting Machine

| Price: | 200000.0 USD |

| Payment Terms: | T/T,L/C,D/A,WU,Paypal |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The equipment is suitable for various veneer gypsum board, calcium silicate board, extruded board, phenolic board, gypsum ceiling.

Specification:

| Dimensions | Length 9600 × width 2910 × height 1250 |

| Working speed | Maximum speed 20 meters per minute |

| Power | 22KW |

| Total mass | 2387kg |

product manual:

The equipment is suitable for various veneer gypsum board, calcium silicate board, extruded board, phenolic board, gypsum ceiling, calcium silicate board, foam board, fire board, glass magnesium board and so on. Split-type high-speed cutting saw, cutting size can be adjusted, cutting thickness 50mm, stable operation, fast cutting speed, high precision, fixed by cylinder pressure, one-button start of the whole cutting stroke, high degree of automation, easy operation, high precision fast.

Features:

1. High-strength cast iron headstock and slewing mechanism, precision bilinear guide

2. Reinforced steel plate body guarantees extremely high rigidity and precision retention

3. Powerful 3.0KW single-phase motor or 4.0KW three-phase motor can be selected.

4. The spindle uses precision tapered roller bearings to maintain maximum rigidity.

5. Poly-V belt drive ensures sufficient smoothness and torque.

6. Ultra-wide high-strength aluminum precision sliding pusher. The main workbench with T-slot facilitates the installation of various accessories.

7. Independent motor drive line saw blade to ensure that the board is cut without burrs.

8. The saw blade can be rotated 0-45 degrees for angle cutting (6128)

Maintenance of panel saw

1. According to the workload, the machine should be regularly dust-removed to ensure the normal heat dissipation of the motor.

2. Regularly dust the pusher track to ensure smooth running of the push table

3. Check the belt regularly and find that the wear should be replaced in time.

4. Regularly fill the lubricating parts of the fuselage to ensure the stability and quietness of the equipment.

Multi-chip saw equipment features

5. The foam concrete slab cutting system adopts advanced automatic control program, automatic cross cutting, vertical cutting, reverse rotation, translation, automatic removal of waste, no need for human operation in the middle, realizing the true foam concrete cutting automation.

6. The whole set of mixing equipment is mainly composed of electronic metering device, automatic feeding device, slurry mixing equipment, touch operating system, etc., automatic batching, electronic metering, high degree of automation, accurate measurement and precise operation and control.

7. User-friendly intelligent operating system. The electrical control adopts the desktop operation console. The main components are international famous brands with interlocking and secondary protection. It is equipped with full Chinese dynamic process operation interface, real-time monitoring and alarm prompts; control system one-button operation, with automatic and manual Function, equipped with emergency manual control operating device. The whole operating system is beautiful and intuitive.

8. The whole production line adopts advanced three-dimensional design and combines the advantages of domestic and foreign models, as well as efficient production and processing technology to ensure the unification of technology and quality. It has the characteristics of reasonable structure design, convenient production and operation, high production efficiency and good product quality.